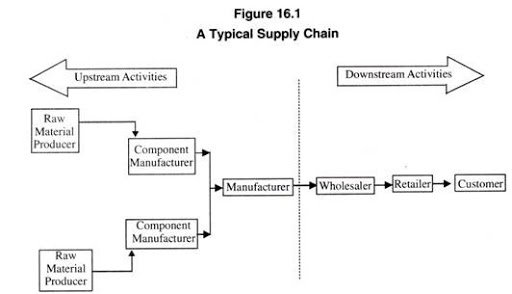

Supply chain management is the management of the flow of goods and services and includes all processes that transform raw materials into final products. It involves the active streamlining of a business’s supply-side activities to maximize customer value and gain a competitive advantage in the marketplace.

SCM represents an effort by suppliers to develop and implement supply chains that are as efficient and economical as possible. Supply chains cover everything from production to product development to the information systems needed to direct these undertakings.

Typically, SCM attempts to centrally control or link the production, shipment, and distribution of a product. By managing the supply chain, companies are able to cut excess costs and deliver products to the consumer faster. This is done by keeping tighter control of internal inventories, internal production, distribution, sales, and the inventories of company vendors.

SCM is based on the idea that nearly every product that comes to market results from the efforts of various organizations that make up a supply chain. Although supply chains have existed for ages, most companies have only recently paid attention to them as a value-add to their operations.

In SCM, the supply chain manager coordinates the logistics of all aspects of the supply chain which consists of five parts:

- The plan or strategy

- The source (of raw materials or services)

- Manufacturing (focused on productivity and efficiency)

- Delivery and logistics

- The return system (for defective or unwanted products)

The supply chain manager tries to minimize shortages and keep costs down. The job is not only about logistics and purchasing inventory. According to Salary.com, supply chain managers, “make recommendations to improve productivity, quality, and efficiency of operations.”

Improvements in productivity and efficiency go straight to the bottom line of a company and have a real and lasting impact. Good supply chain management keeps companies out of the headlines and away from expensive recalls and lawsuits.

Supply Chain Strategies are the critical backbone to Business Organizations today. Effective Market coverage, Availability of Products at locations that hold the key to revenue recognition depends upon the effectiveness of Supply Chain Strategy rolled out. Very simply stated, when a product is introduced in the market and advertised, the entire market in the country and all the sales counters need to have the product where the customer can buy and take delivery. Any glitch in the product not being available at the right time can result in the drop in customer interest and demand which can be disastrous. Transportation network design and management assume importance to support sales and marketing strategy.

Inventory control and inventory visibility are two very critical elements in any operations for these are the cost drivers and directly impact the bottom lines on the balance sheet. Inventory means value and is an asset to the company. Every business has a standard for inventory turnaround that is optimum for the business. Inventory turnaround refers to the number of times the inventory is sold and replaced over a period of twelve months. The health of the inventory turn relates to the health of business.

In a global scenario, the finished goods inventory is held at many locations and distribution centers, managed by third parties. A lot of inventory would also be in the pipeline in transportation, besides the inventory with distributors and retail stocking points. Since any loss of inventory anywhere in the supply chain would result in loss of value, effective control of inventory and visibility of inventory gains importance as a key factor of Supply Chain Management function.

Example of SCM

Understanding the importance of SCM to its business, Walgreens Boots Alliance Inc. placed focused effort on transforming its supply chain in 2016. The company operates one of the largest pharmacy chains in the United States and needs to efficiently manage and revise its supply chain so it stays ahead of the changing trends and continues to add value to its bottom line.

As of July 5, 2016, Walgreens has invested in the technology portion of its supply chain. It implemented a forward-looking SCM that synthesizes relevant data and uses analytics to forecast customer purchase behavior, and then it works its way back up the supply chain to meet that expected demand.

For example, the company can anticipate flu patterns, which allow it to accurately forecast needed inventory for over-the-counter flu remedies, creating an efficient supply chain with little waste. Using this SCM, the company can reduce excess inventory and all of the inventories’ associated costs, such as the cost of warehousing and transportation.

- Supply chain management (SCM) is the centralized management of the flow of goods and services and includes all processes that transform raw materials into final products.

- By managing the supply chain, companies are able to cut excess costs and deliver products to the consumer faster.

- Good supply chain management keeps companies out of the headlines and away from expensive recalls and lawsuits.

Functions

A supply chain includes all efforts pertaining to the production and delivery of a product/service from suppliers to customers. SCM includes:

- The management of demand and supply

- Raw materials and parts sourcing

- Manufacturing and/or assembly

- Warehousing

- Tracking inventory

- Order Management

- Distribution across multiple channels

- Delivery to the customer

Supply Chain Management plays a crucial role in the success of the enterprise and customer satisfaction. The knowledge of SCM can also be leveraged to support disaster relief operations, medical missions, and handle similar emergencies.

Any business needs resources to trade. Further, it uses these resources to create products/services which the consumers are willing to pay for. This is known as the ‘transformation process’.

Participants

Producers

Producers or manufacturers are organizations that make a product. This includes companies that are producers of raw materials and companies that are producers of finished goods. Producers of raw materials are organizations that mine for minerals, drill for oil and gas, and cut timber. It also includes organizations that farm the land, raise animals, or catch seafood. Producers of finished goods use the raw materials and sub-assemblies made by other producers to create their products.

Distributors

Distributors are companies that take inventory in bulk from producers and deliver a bundle of related product lines to customers. Distributors are also known as wholesalers. They typically sell to other businesses and they sell products in larger quantities that an individual consumer would usually buy. Distributors buffer the producers from fluctuations in product demand by stocking inventory and doing much of the sales work to find and service customers. For the customer, distributors fulfill the “Time and Place” function – they deliver products when and where the customer wants them.

Retailers

Retailers stock inventory and sell in smaller quantities to the general public. This organization also closely tracks the preferences and demands of the customers that it sells to. It advertises to its customers and often uses some combination of price, product selection, service, and convenience as the primary draw to attract customers for the products it sells. Discount department stores attract customers using price and wide product selection. Upscale specialty stores offer a unique line of products and high levels of service. Fast food restaurants use convenience and low prices as their draw.

Customers

Customers or consumers are any organization that purchase and use a product. A customer organization may be an organization that purchases a product in order to incorporate it into another product that they in turn sell to other customers. Or a customer may be the final end user of a product who buys the product in order to consume it.

One thought on “Supply Chain Management Systems”